Production

Our flexible polyurethane foam is renowned for its comfort and quality, refined over more than 65 years of production. It is highly valued in Europe and the USA for its excellent properties.

Within the Sandella group, we also have expertise in 3D design, scanning, milling, and manual modeling. We produce products in steel and aluminum and can also offer products in wood and plastic through our suppliers and partners.

Our main product is flexible moulded polyurethane foam, which we produce in the following variants:

Standard Polyurethane Foam: Suitable for most standard applications in Europe, the USA, and Asia.

Flame-Retardant Polyurethane Foam: Meets stricter requirements, such as those for the UK market, railways, public transport, etc. We offer foam variants that comply with both BS5852 Crib 5 and EN 45545 standards.

Viscoelastic Foam: This foam slowly returns to its original shape after compression.

Flame-Retardant Viscoelastic Foam: Similar to viscoelastic foam but meets UK fire safety standards.

Integral Foam: A denser foam with a higher weight, commonly used for armrests on office chairs, truck seats, etc.

The biggest quality difference in a piece of furniture, lies in the foam

Always check the padding in the furniture first.

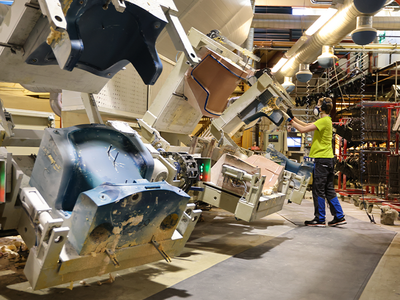

In a computer-controlled system, raw materials enter a closed production process. This ensures consistent quality and maximum utilization of the raw materials.

The production process is highly flexible, allowing us to meet most quality requirements.

The filling of the moulds is also automated. This takes place on various production lines, resulting in a rational and flexible production process.

Once the chemical reaction is complete, the product is 100% stable and does not emit any polluting gases or residues. The production process generates very little waste and requires no additional energy for foaming or curing. It also results in minimal air emissions and no other environmental discharges. Additionally, there are no cleaning processes for the foam in production, unlike some other types of foam

Moulded cushions from Sandella provide first-class seating, comfort and durability

High resilience and a very good side support, provide maximum seating comfort no matter where you sit in the furniture.

The unparalleled properties of cold foam also ensures the correct seating depth throughout the product's lifetime.

Moulding ensures that softness and resilience are tailored to this product, providing the desired seating comfort.

Moulded cushions are especially durable. Even after several years of use, the cushions will retain their original shape and quality.

Moulded cold foam has significantly better properties than other alternatives. This applies to both pressure deformation and the ability to withstand compression without collapsing.

SANDELLA GUARANTEES THAT THE CUSHIONS WILL RETAIN THEIR ORIGINAL SHAPE, RESILIENCE, AND COMFORT FOR AT LEAST 10 YEARS